Smart Pack®

Smart Pack®

Unit Dose Packaging System

Unit Dose Packaging System

SmartPack® is a reliable and efficient Unit Dose Packaging System designed for oral solid medications. This high-performance solution streamlines the packaging process, eliminating the need for manual packaging and sorting while ensuring accuracy and compliance. With its user-friendly operation and low-maintenance design, SmartPack® provides a cost-effective solution for pharmacies looking to enhance their unit-dose packaging processes.

How It Works : Smart Pack® in Action

The SmartPack® Unit Dose Packaging System efficiently packages and barcodes tablets up to 55 packs per minute, ensuring accuracy and compliance.

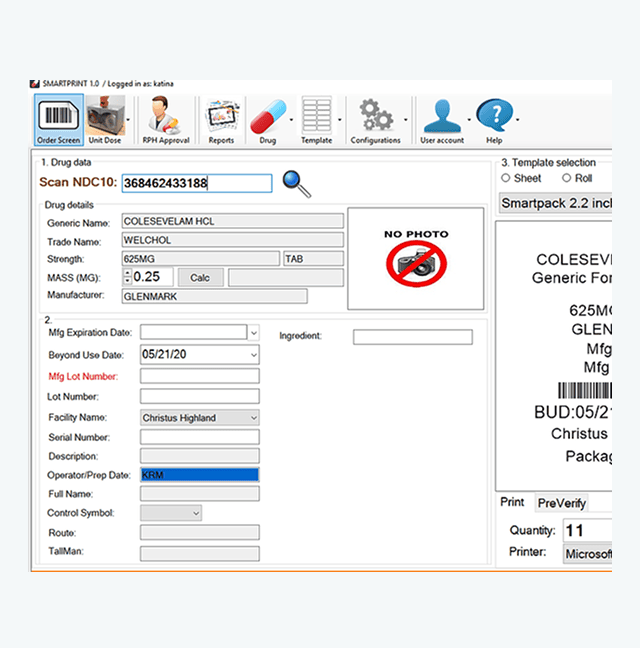

Pharmacy staff can securely access the SmartPack® software using various sign-in methods, including biometric authentication. They can retrieve drug information from the pre-loaded drug product database.

The barcode scanner verify previously selected drug information retrieves key details like manufacturing date, expiry date, and lot number from the medication bottle and inputs it into the software. Afterward, the bottle is opened, and the medications are placed into designated slots in the machine.

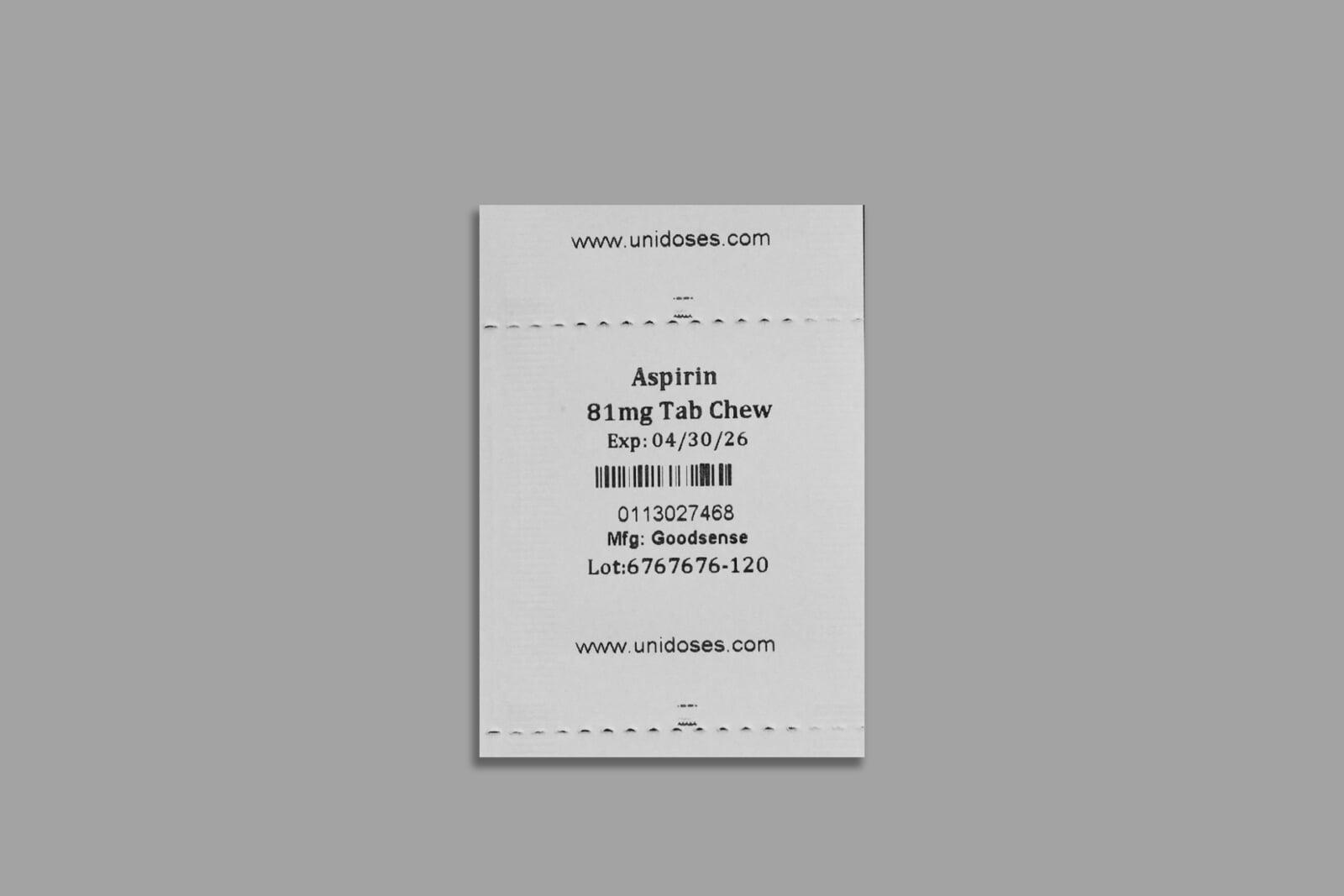

Pill detection sensor identifies each pill in its respective slot, transferring it to the calibration-free dispensing system, where it is individually labelled and packaged with precision. Finally, a built-in scanner verifies each packet, ensuring that the printed information is accurate and scannable for seamless tracking.

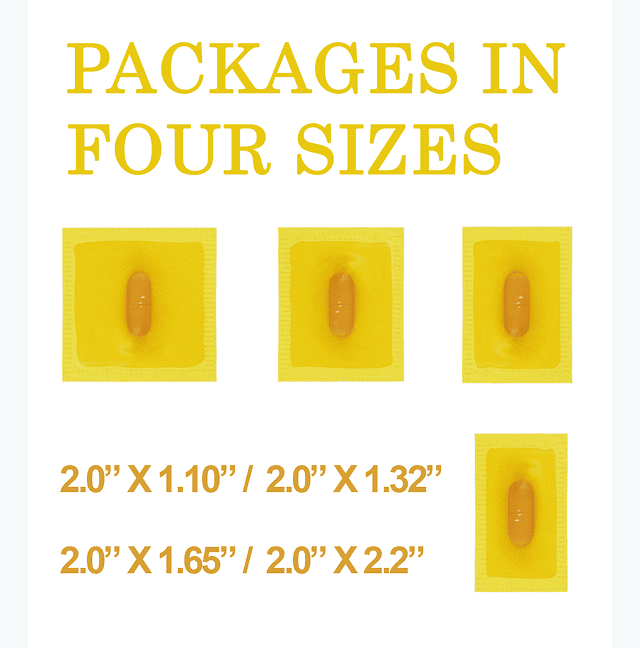

Pouch Sizes

Pouch Sizes

- Supports multiple pouch sizes: 2.0” x 1.10”, 1.32”, 1.65”, and 2.2”

- Smart material-saving function that automatically selects the appropriate pouch size based on the medication's dimensions

Barcode

- Supports high-resolution 1D and 2D barcodes (Data Matrix, Aztec, QR, GS1)

- Allows custom barcodes with multiple data fields, text, and dates

Smart Print

- Unit-Dose Packaging System comes with Built-In Smart Print software pre-installed for smooth operation

Features of Smart Pack® Unit Dose Packaging System

55 Packages Per Minute

Efficiently produces up to 55 packages per minute, optimizing productivity in medication packaging workflows

Calibration-Free Dispensing

Calibration-Free Dispensing

Calibration free dispensing ensures accurate dosage without manuel adjustments

GS1 Barcode Scanner

GS1 Barcode Scanner

Extracts manufacturing date, expiration, and lot number from GS1 barcodes, ensuring accurate tracking and traceability.

Packages In Four Sizes

Packages In Four Sizes

Offers four package size options (2.0" x 1.10", 1.32", 1.65", 2.2") for versatile medication packaging.

Built-In Barcode Scanner

Built-In Barcode Scanner

Verifies each package's scannability and accuracy, ensuring correct information is encoded.

Customizable Printing Options

Customizable Printing Options

Print instructions on medicine packages in any language with easy-to-use software.

Pill Orientation Technology

Pill Orientation Technology

Patented pill orientation technology prevents tablet crushing by centering pills within the pouch, away from sealing areas.

Dedicated Customer Support

Dedicated Customer Support

We provide on-site repairs and assistance to quickly resolve any technical issues.

Narcotic Drug Safety with Smart Pack® Unit Dose Packaging System

Handling narcotic or controlled medications requires precision, security, and compliance with regulations. Automatedpouch packaging solutions like SmartPack® streamline dispensing, improve patient safety, and enhance inventory control.

Regulatory Compliance

Ensures accurate tracking, tamper-proof packaging, and audit readiness.

Patient Safety

Minimizes medication errors with barcoded, unit-dose pouches.

Pharmacy Efficiency

Reduces workload, prevents waste, and optimizes inventory management.

Product Information

Product Information

| VALUE |

|---|---|

| Manufacturer | Unidoses |

| Country of Origin | USA |

| Weight | 60 Pounds |

| Packaging Speed | 55 packages per min |

Dimensions | 14"H x 26"L x 15"D |

| Power | 115VAC,60Hz, 320VA & 230VAC, 50Hz,320VA |

| Sealing | 93 °C , no degradation to medication, no fumes |

| Pill Per Pouch | 1 |

| Canister | No |

| Integration | QSI, Computer Rx, Pioneer Rx and Many More |

| Built-in Computer | Yes |

FAQ

FAQ

1. What is a unit dose tabletop pouch packaging machine?

A unit dose tabletop pouch packaging machine is a compact, automated system used in pharmacies to package individual doses of medication into single-use pouches. These machines not only fill and seal the pouches but also print labels and barcodes for tracking and identification purposes, ensuring medication accuracy and patient safety.

2. How does the unit dose tabletop pouch packaging machine work?

The machine typically works by:

● Filling the pouch with a precise dose of medication (Solid Oral medication).

● Sealing the pouch using heat or another sealing method to ensure the dose is securely enclosed.

● Printing labels directly onto the pouches, including information like medication name, dosage instructions, expiration date, and barcodes for easy scanning, tracking and also customized printing.

3. Why is barcode printing important in pharmacy packaging?

Barcode printing allows pharmacies to:

● Ensure the accurate identification of medications.

● Maintain traceability for inventory and patient safety.

● Comply with regulatory standards that require barcodes for medication management.

● Prevent errors in medication administration and enhance workflow efficiency.

4. Is the Unit Dose Packaging System easy to use?

Yes, unit dose tabletop pouch packaging machines are user-friendly. Most models come with a touchscreen interface, clear instructions, and minimal manual handling required. They are designed to be compact, making them suitable for pharmacies with limited space. However, basic training may be required to ensure efficient use.

5. Can the Unit Dose Packaging machine handle different pouch sizes?

Our unit dose tabletop pouch packaging machines are adjustable and can handle various pouch sizes. This flexibility is important for accommodating different medication forms (e.g., larger pouches for tablets or smaller pouches for capsules).

6. What features should I look for when purchasing Unit Dose Packaging machine?

Key features to consider include:

● Labeling and barcode printing functionality.

● Adjustable pouch size settings for different medications.

● Accuracy and weight control systems to ensure correct dosage.

● Automatic sealing to prevent contamination.

● User-friendly interface for easy operation.

● Ease of maintenance and availability of customer support.

7. What is the average speed of Unit Dose Packaging machine?

The speed of unit dose tabletop pouch packaging machines can vary depending on the model and the type of medication. On average, Our machines can produce 55 pouches per minute.

8. How do I maintain Unit Dose Packaging machine?

Regular maintenance tasks typically include:

● Cleaning the machine’s filling, sealing, and labeling components.

● Calibrating our machine is usung a calibration free canister.

● Replacing consumables like labels, print ribbons, and pouches.

● Routine inspections to ensure all mechanical parts are functioning correctly.

Check with the manufacturer for specific maintenance schedules and service contracts for ongoing support.

9. Is the Unit Dose Packaging machine suitable for high-volume pharmacies?

Yes, many unit dose tabletop pouch packaging machines are capable of high throughput, especially those designed for medium to large-scale operations. For high-volume needs please contact the sales team for the best assistance.

10. Can the Unit Dose Packaging Machine be integrated with pharmacy management systems?

Yes, Our unit dose packaging machines are integrated with pharmacy management systems (PMS) to enhance workflow and data tracking. Integration with the system can automate the recording of patient-specific information, medications, and barcodes for easy scanning during dispensing.

11. What is the costs of unit dose tabletop pouch packaging machines?

Please contact the sales team for more information.